News

The Benefits of Using Industrial Steam Boilers System in Manufacturing Processes

Industrial steam boilers are highly important machines that play a critical role in various industries. These boilers are large, powerful and highly efficient. They are used to generate steam that is used to power machines and equipment throughout manufacturing facilities, power plants, and industrial plants. The steam produced by these boilers can be used for various applications such as heating, sterilization, and the generation of electricity. Without steam boilers, many industries would not be able to function and would suffer from major production losses. The importance of steam boilers cannot be overstated. With their ability to generate high-pressure steam, these boilers are able to provide the power needed to run heavy machinery and other industrial equipment.

They are also highly efficient and cost-effective, able to generate vast quantities of steam while consuming relatively little fuel. This is essential for industries that need to keep operating costs as low as possible. In addition to their importance in powering machines and equipment, steam boilers are also essential for heating facilities and keeping them operational. By providing a constant source of heat, boilers help to maintain a safe and comfortable working environment for employees. Overall, the role of industrial steam boilers is vital to the success and operations of many industries, and they will continue to be an indispensable part of industrial processes for years to come.

Why Choose An Efficient Steam Boiler Is Crucial For Businesses

An efficient steam boiler is a vital component for businesses that require a steady supply of hot water or steam. Inefficient boilers can lead to wastage of energy and increased operational costs, which ultimately impact the profitability of the company. A reliable and efficient steam boiler ensures a consistent supply of hot water or steam, which is critical for running various industrial processes. In addition, an efficient boiler also reduces the risk of downtime and delays caused by equipment failure, which can significantly impact production schedules. Furthermore, an efficient boiler also plays a crucial role in reducing a company's carbon footprint, which is essential for environmental sustainability. Investing in an efficient steam boiler is, therefore, an excellent business decision that can help reduce operational costs, improve productivity, and enhance the company's overall performance. In conclusion, having an efficient steam boiler is not only a necessity but also a crucial component for companies that desire to remain competitive and sustainable in today's industrial landscape.

What Is An Industrial Steam Boiler

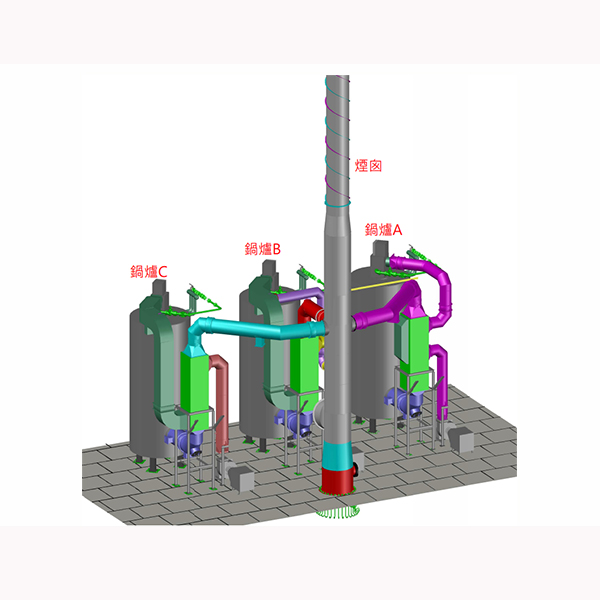

Industrial steam boilers are large vessels used to generate steam for various industrial processes. They function by combusting fuel, such as natural gas, oil, or coal, to heat water and produce steam. The steam can then be used for heating, power generation, or other manufacturing processes. Industrial steam boilers vary in size and design, with some capable of producing over 10 million pounds of steam per hour. To ensure the safe and efficient operation of these boilers, they require skilled operators and careful maintenance. The use of steam boilers is critical in many industries, including food processing, chemical manufacturing, and power generation. Properly functioning steam boilers can increase efficiency, reduce energy costs, and improve overall productivity. As a cornerstone of many industrial operations, it is important to understand the role of industrial steam boilers and ensure their proper operation for a safe and effective manufacturing process.

Different Types of Steam Boilers and Their Uses

In the industrial sector, steam boilers are widely used to generate steam for various applications. Different types of steam boilers are available, each with specific uses and functionalities. The most common types include fire-tube boilers, water-tube boilers, and electric boilers. Fire-tube boilers heat the water in tubes through combustion, producing hot gas that passes through these tubes to produce steam. Water-tube boilers, on the other hand, heat the water that passes through the tubes and is heated by the heat source outside the tubes. Electric boilers, which do not require any fuel, use electricity to heat the water directly, creating steam. The uses for these boilers range from power generation to providing heat for buildings or industrial process applications. Understanding the different types of steam boilers and their functionalities helps industries determine the best fit for their needs and ensures efficient, reliable, and safe operation.

Components of An Industrial Boiler

An industrial steam boiler is a complex machine that is used to generate steam for various industrial processes. The boiler consists of several components that work together to produce steam efficiently and safely. The key components of an steam boiler include the feedwater system, combustion system, heat exchanger, safety valve, and control system. The feedwater system is responsible for supplying water to the boiler, which is then heated and converted into steam by the combustion system. The heat exchanger plays a crucial role in transferring the heat generated by the combustion system to the water. The safety valve releases excess pressure in the boiler to prevent accidents, while the control system regulates and monitors the temperature and pressure of the boiler. Each component of an steam boiler is designed to work in tandem to ensure optimal steam production and avoid hazardous conditions. A well-maintained and properly functioning steam boiler is crucial for the smooth operation of industrial processes and the safety of workers.

How Do Industrial Steam Boilers Work

An industrial steam boiler is a device that converts water into steam using fuel or electric energy. The basic operating principle of this type of boiler is based on the transfer of heat generated by the burning of fuel or the application of an electrical current to the water inside the boiler. The transfer of heat raises the temperature of the water in the boiler until it reaches boiling point, producing steam that can be used for different purposes, such as heating or power generation. To ensure efficient operation, a steam boiler depends on various factors, including the design of the furnace, the fuel being used, and the management of the boiler's water level, pressure, and temperature. Proper maintenance and training of personnel are also critical elements in ensuring safe and reliable operation. A well-operated steam boiler can offer significant cost savings and increased efficiency in many industries.

The production of steam is often implemented through the use of heat energy, which can be acquired either through burning fuel or obtaining it from other sources. The creation of steam takes place through a combination of several processes, such as combustion, heat exchange, and boiler operation. First, fuel combustion occurs which releases heat energy, which then heats a fluid within a boiler. This fluid is usually water or any other heat transfer medium. The heat exchange process makes sure that the fluid gets the right temperature and pressure required to create steam. The steam then travels through a turbine where it is expanded, resulting in the conversion of the stored energy into mechanical energy. Finally, the turbine's mechanical energy is converted into electrical energy through the use of a generator. Therefore, many mechanized operations require steam, and the generation process involves various steps to ensure it is efficient and effective.

Benefits of Using Industrial Steam Boilers

Steam boilers are widely used in industries due to their numerous advantages. Firstly, they provide a high level of efficiency in terms of energy consumption, as they can convert up to 95% of the fuel energy into steam. This results in cost-effectiveness for the manufacturer, who can save on fuel bills. Secondly, they are reliable and durable, as they are built with high-quality materials such as steel. This means that they can operate with minimal maintenance and repairs, leading to less downtime and increased productivity. Thirdly, steam boilers offer flexibility, as they can be adjusted to meet the specific needs of a particular industry. They can produce steam at various pressures and temperatures, which is crucial for industries that require a particular steam quality. Finally, steam boilers help to reduce carbon emissions, making them an environmentally friendly option. Overall, the use of steam boilers is a wise choice for industries looking to boost efficiency, reduce costs, and enhance sustainability.

Steam boilers have long been an integral component of industrial machinery, and their ability to increase productivity cannot be overstated. Steam boilers can provide a constant supply of high-pressure steam, which can power turbines or drive machinery such as pumps, fans, and compressors. Increased pressure and temperature levels can also help to reduce cooking, heating, and drying times, ultimately leading to faster and more efficient production processes. Moreover, steam boilers are highly efficient and require minimal maintenance, which translates into savings in both energy and labor costs. Additionally, with the availability of advanced control systems, steam boilers can be easily programmed to operate at optimal efficiency, thus ensuring the highest possible productivity levels. By providing a reliable and consistent source of energy, steam boilers help businesses to streamline their operations, reduce downtime, and ultimately maximize profits. It is thus clear that the implementation of steam boilers can offer significant advantages for any industrial operation seeking to boost productivity and competitiveness.

Steam boilers are highly effective at improving energy efficiency in a variety of settings. By using water as a heating medium, steam boilers are able to generate heat through a process called thermal fluid heating. This eliminates the need for traditional combustion-based heating technologies, which can be expensive, polluting and wasteful. Furthermore, steam boilers are highly efficient at extracting heat from the water, allowing them to achieve high levels of energy utilization. This translates into reduced fuel consumption and lower operating costs, while also minimizing the environmental impact of energy production. Additionally, steam boilers can be easily integrated with other renewable energy sources such as solar and wind power, further reducing the reliance on traditional fossil fuels. Effective maintenance and regular cleaning, also helps to maintain high levels of energy efficiency and reliable operation of steam boilers. Overall, the adoption of steam boilers represents a highly effective way of improving energy efficiency and reducing environmental impact within a range of industrial and commercial settings.

Choosing the Correct Steam Boiler Manufacturer In Industrial Settings

A well-maintained and efficient steam boiler is vital for any industry that uses steam as an energy source. The importance of keeping the boiler in good condition cannot be overemphasized as it directly affects plant productivity and efficiency. A poorly maintained boiler can lead to unexpected downtimes, delays, and even accidents, resulting in loss of time, production, and revenue. Regular inspections, preventive maintenance, and timely repairs can help ensure that the boiler operates at its maximum efficiency, reduces fuel consumption, and extends its lifespan. It is necessary to have trained and skilled professionals carry out inspections, maintenance, and repairs to avoid any potential risks and ensure that the boiler complies with safety regulations. A well-functioning steam boiler also guarantees a safer working environment for employees by preventing exposure to harmful emissions and reducing the risk of fire and explosions. Therefore, industries should prioritize investing in maintaining and upgrading their steam boilers to prevent potential risks and ensure a smooth and efficient production process.